Foam performance starts with the right polyols for polyurethane manufacturing

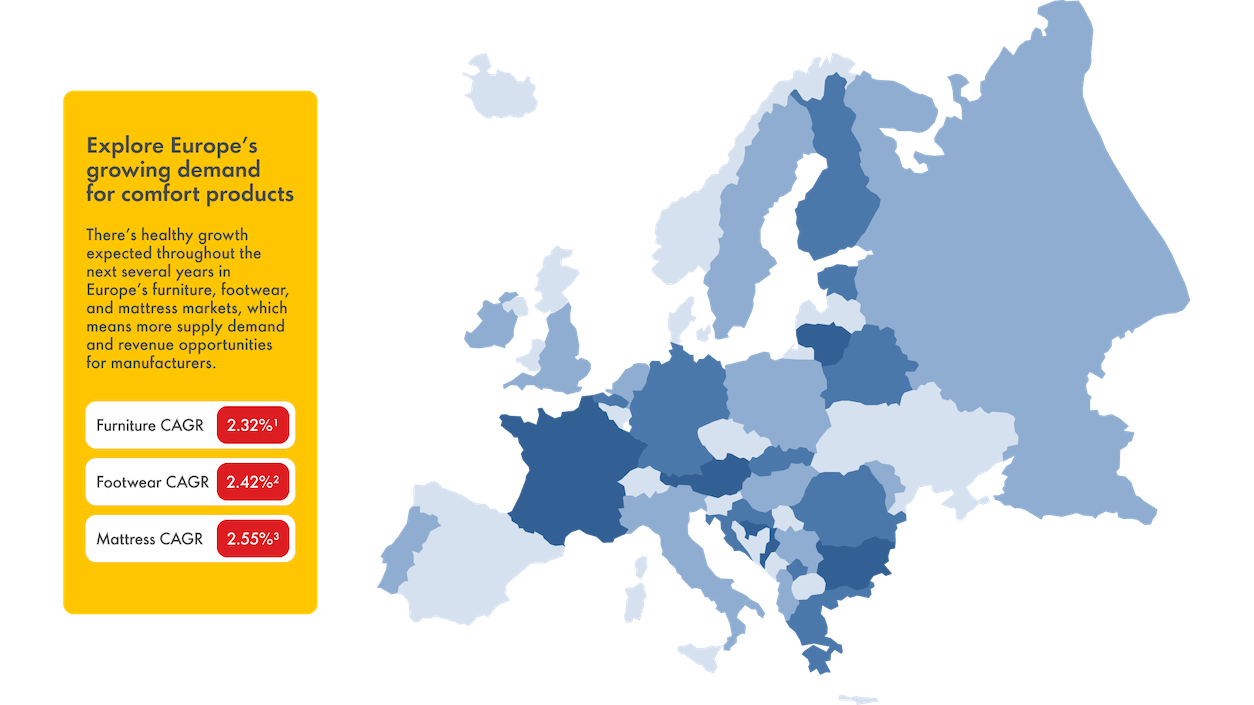

In polyurethane foam manufacturing, consistency and comfort depend on the chemistry behind the formulation. For furniture, footwear, and mattresses, each foam type requires the right balance of structure, density, and flexibility to meet consumer expectations.

Polyols for foam play a critical role in achieving these results. They determine how a product feels, performs, and supports the user over time. This affects key qualities like breathability and load-bearing strength.

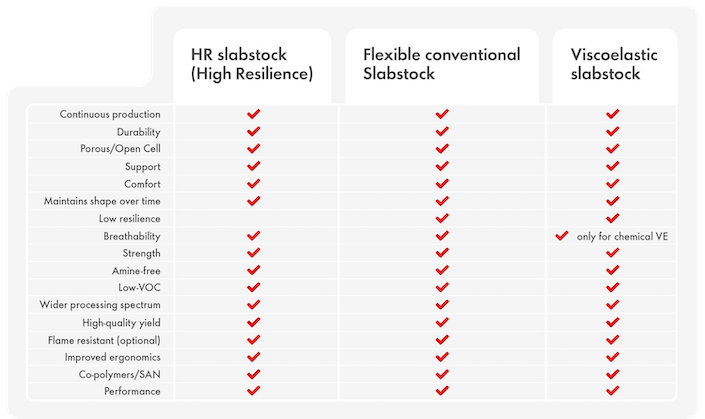

To help manufacturers achieve reliable results at scale, Shell CARADOL® polyols provide consistent quality and process efficiency for flexible slabstock foam, viscoelastic foam, and cold-cure moulding applications.